When the power goes out, the hum of a Generac standby generator is music to many homeowners' ears. But before you experience that peace of mind, you’re likely grappling with the initial question: what exactly are the Generac generator installation costs? The truth is, there’s no single price tag. From the size of the unit to the quirks of your property, numerous factors converge to determine the final investment. Think of it less as buying a product and more as investing in a tailored home resilience solution.

This comprehensive guide will break down what goes into the total cost, helping you budget wisely and make informed decisions.

At a Glance: Your Generac Installation Cost Expectations

- Total Range: Most standard Generac standby systems installed range from $4,000 to $12,000, though complex setups can push past $15,000.

- Unit Cost: The generator itself typically runs $3,000 to $6,000, depending on size and features.

- Basic Installation Labor: Expect $1,000 to $3,000 for the core setup by professionals.

- Electrical Upgrades: Often the wild card, these can add $1,000 to $4,000 or more if your home needs significant panel work.

- Key Drivers: Generator size (kW), site accessibility, and the extent of electrical and fuel line upgrades are the biggest influencers.

- Saving Tips: Proper sizing for essential circuits, off-peak season installation, and comparing multiple quotes can help trim costs.

Beyond the Sticker Price: Understanding Generac Generator Installation Costs

Many homeowners focus solely on the price of the generator unit, often surprised by the final bill. The reality is that the generator itself is just one component of a complete, professionally installed standby system. The bulk of the expense beyond the unit comes from skilled labor, site preparation, electrical upgrades, and permitting.

Let’s unpack these key components to give you a clearer picture of what you're paying for.

The Generator Itself: Sizing Up Your Needs

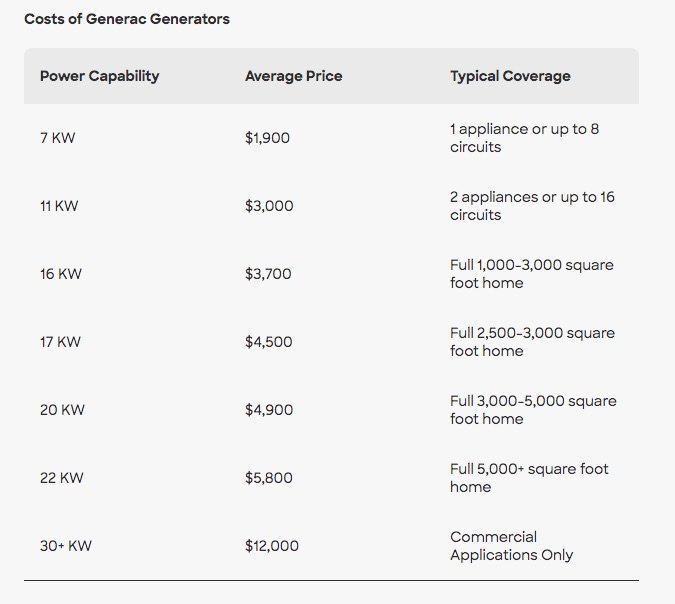

Naturally, the specific Generac model you choose is a major cost factor. Generac offers a wide array of standby generators, from smaller units designed to power essential circuits to large whole-home systems. The primary differentiator is kilowatt (kW) output, which dictates how much electricity the generator can produce.

- Smaller Units (8-10 kW): These are typically sufficient for powering critical circuits like your refrigerator, sump pump, a few lights, and a furnace fan. They are the most affordable option, both in terms of unit cost and installation complexity.

- Mid-Range Units (12-16 kW): A popular choice for many homes, these can handle more comforts, including larger appliances, central air conditioning, and more circuits, offering a good balance of capability and cost.

- Larger Units (18-26 kW+): Designed for whole-house backup in larger residences or those with extensive electrical needs. These units come with a higher price tag and often require more substantial electrical and fuel line infrastructure.

Beyond kW, features like mobile monitoring, advanced controllers, and specialized enclosures can also influence the unit's price. When considering how much Generac generators cost, remember this initial investment is foundational to your total project budget.

Professional Installation: The Labor and Logistics

This is where the specialized expertise truly comes into play. Installing a Generac standby generator isn't a DIY job; it requires licensed electricians, plumbers (or gas fitters), and experienced general contractors. They ensure the unit is safely and correctly integrated into your home's electrical and fuel systems, complying with all local codes.

Typical installation tasks include:

- Placement and Leveling: The generator needs a stable, level base, often a concrete pad, away from windows, doors, and property lines as per code.

- Electrical Connections: This involves connecting the generator to your home's main electrical panel through an automatic transfer switch (ATS). The ATS is crucial as it senses power outages, starts the generator, and safely transfers your home's load without backfeeding the grid.

- Fuel Line Installation: Depending on whether you're using natural gas or propane, a qualified professional must run a dedicated fuel line from your source to the generator.

- Battery Installation: Standby generators use a small battery for starting, similar to a car.

- Testing and Commissioning: Ensuring the system runs correctly and performs self-tests.

Labor is a significant cost factor, with licensed electricians typically charging $75 to $125 per hour, and potentially more in urban markets. A standard residential installation can require 10 to 40 labor hours, influenced heavily by the complexity of the site and your home's existing infrastructure.

Electrical Upgrades: Powering Your Home Safely

Often, installing a Generac generator reveals the need for upgrades to your home's existing electrical system. These aren't always anticipated but are critical for safe and efficient operation.

Common electrical upgrades include:

- Service Panel Upgrades: If your current electrical panel isn't robust enough to handle the generator's output or the new wiring, an upgrade may be necessary.

- Sub-panels: Sometimes a dedicated sub-panel is installed to manage the circuits the generator will power, especially for partial-home coverage.

- Wiring and Conduits: Longer runs of electrical conduit from the generator to the transfer switch and panel will increase material and labor costs.

- Grounding: Ensuring proper grounding for the new electrical components is paramount for safety.

These upgrades can be a substantial portion of the overall cost, ranging from $1,000 to $4,000, and sometimes more for older homes with outdated electrical systems.

Site Prep and Fuel Line Extensions: Beyond the Basics

The physical location of your generator plays a big role in installation costs.

- Concrete Pad: Most Generac units require a level concrete pad to sit on. If one needs to be poured, it adds to the cost. Pre-fab composite pads can be a cheaper alternative.

- Trenching: If your generator is located far from your electrical panel or natural gas line, trenching may be required to bury electrical conduits and fuel lines. This is labor-intensive and adds significant cost.

- Fuel Source Proximity: The further the generator is from your natural gas meter or propane tank, the longer and more expensive the fuel line installation becomes. If you opt for propane, you'll also need to consider the cost and placement of a dedicated propane tank.

Permits, Inspections, and Red Tape

Don't forget the administrative side of things. Installing a standby generator is a significant home modification and almost always requires permits from your local municipality. These ensure the installation adheres to local building, electrical, and plumbing codes for safety and compliance.

- Permit Costs: These vary widely by location but generally range from a few hundred dollars to over a thousand.

- Inspections: After installation, multiple inspections (electrical, plumbing, building) are typically required before the system can be officially commissioned. These are included in the permit process.

Factor these "paperwork" costs, usually a few hundred dollars, into your budget. Skipping permits might seem like a way to save money, but it can lead to hefty fines, insurance issues, and problems when you try to sell your home.

Typical Generac Installation Cost Ranges: What to Expect

While every installation is unique, we can provide some general ranges based on common Generac standby generator setups for standard homes. Remember, these are estimates, and your actual costs will vary.

- Entry-Level Systems (8-10 kW): $4,000 - $7,000

- Suitable for essential circuits: refrigerator, a few lights, sump pump, furnace fan.

- Generally for smaller homes or those with minimal backup needs.

- Installation is typically straightforward with close proximity to electrical and fuel sources.

- Mid-Range Systems (12-16 kW): $7,000 - $12,000

- Can power most essential circuits plus some comforts like central AC, water heater, more appliances.

- Popular for average-sized homes seeking a good balance of backup power and cost.

- May involve some minor electrical upgrades or slightly longer runs for fuel/electrical lines.

- Premium Systems (18-26 kW+): $12,000 - $20,000+

- Designed for whole-home backup, even for larger residences with high electrical demands.

- Often involves significant electrical panel upgrades, longer fuel line runs, or complex site preparation.

- The unit itself is more expensive due to higher output capacity and features.

These ranges assume a typical suburban installation. Factors like difficult terrain, extreme weather conditions during installation, or highly complex electrical systems in older homes can push costs beyond these averages.

Real-World Generac Installation Examples

To illustrate the variations, let’s look at some hypothetical scenarios based on typical installations.

The Essential Backup: Basic 8 kW System

- Scenario: Small suburban home (1,500 sq ft) with modern electrical panel, natural gas line readily available, flat lot, generator placed close to the service panel.

- Generator (8 kW): $1,800

- Automatic Transfer Switch (ATS): $1,000

- Labor (approx. 15-20 hours): $2,200

- Permits, Delivery, Basic Materials: $250

- Total Estimated Cost: $5,450

Comfort and Convenience: Mid-Range 12 kW System

- Scenario: Average-sized family home (2,500 sq ft) with slightly older electrical panel needing minor adjustments, natural gas line available but requires a 20-foot extension, concrete pad needed.

- Generator (12 kW): $3,200

- Automatic Transfer Switch (ATS): $1,200 (for slightly larger capacity)

- Labor (approx. 30-35 hours): $3,800

- Permits, Delivery: $420

- Electrical Upgrades/Accessories (e.g., concrete pad, minor panel work): $800

- Total Estimated Cost: $9,420

Whole-Home Powerhouse: Premium 16-22 kW System

- Scenario: Large custom home (4,000 sq ft+) requiring whole-house backup, older 200-amp electrical service needing significant upgrade, generator placed on the opposite side of the house from the natural gas meter, requiring 50+ feet of trenching.

- Generator (16-22 kW): $5,500

- Automatic Transfer Switch (ATS): $1,400 (heavy-duty)

- Labor (approx. 60+ hours due to trenching, panel work): $7,200

- Permits, Delivery (more complex): $1,000

- Major Upgrades/Accessories (e.g., service panel upgrade, extensive trenching, larger fuel line): $2,000

- Total Estimated Cost: $17,100

These examples clearly illustrate how site-specific conditions and your desired level of power backup dramatically influence the final price.

Drilling Down: Factors That Drive Your Generac Costs Up (and Down)

Understanding the granular details can help you anticipate expenses and potentially find ways to optimize your project.

Generator Size (kW) and Type

As discussed, larger generators capable of powering more of your home cost more. Beyond just the unit price, larger units often require:

- Larger Automatic Transfer Switches: More robust ATS units are needed to handle higher electrical loads.

- Thicker Gauge Wiring: To safely carry more current, heavier gauge electrical wire is necessary, which is more expensive per foot.

- Larger Fuel Lines: Natural gas or propane lines need to be appropriately sized to ensure the generator gets enough fuel, potentially requiring new or upgraded piping.

Site Accessibility and Location Challenges

Where you plan to put the generator can significantly impact labor and material costs.

- Distance to Electrical Panel/Fuel Source: Long runs for electrical conduit or gas lines mean more material and more labor hours for trenching (if lines are buried) or running surface-mounted lines.

- Terrain: Rocky soil, steep slopes, or uneven ground for the generator pad can increase site preparation costs.

- Obstructions: Dealing with existing landscaping, fences, or other structures can add time and effort.

- Space Constraints: Tight spaces can make maneuvering equipment and performing work more difficult.

Your Home's Existing Electrical Service

This is one of the most unpredictable cost factors.

- Panel Capacity: An older home with a 100-amp service panel may need a full upgrade to 200 amps or more to handle a whole-house generator, a substantial expense.

- Condition of Wiring: Outdated or non-compliant wiring can lead to unexpected upgrades during inspection.

- Number of Electrical Panels: Homes with multiple sub-panels or complex electrical layouts can increase the intricacy of integrating the ATS.

Fuel Source and Infrastructure (Natural Gas vs. LP)

Generac generators typically run on natural gas or liquid propane (LP).

- Natural Gas: Often the most convenient and cost-effective if you already have a natural gas line to your home. However, your existing gas meter might need an upgrade from the utility company to handle the generator's demand, which can have its own costs and lead times.

- Liquid Propane (LP): Ideal if natural gas isn't available. You'll need a large propane storage tank on your property (typically 250 or 500 gallons for standby units). The tank itself can be leased or purchased, and its installation, including the concrete pad, adds to the initial setup cost. Regular refills are also an ongoing expense.

Regional Differences and Market Dynamics

Just like housing prices, installation costs for Generac generators vary by geographic region and local market conditions.

- Labor Rates: Hourly rates for electricians and plumbers are higher in urban, high cost-of-living areas (e.g., coasts) than in rural or lower cost-of-living areas (e.g., Midwest or Southwest).

- Coasts (Urban): +5% to +15% above national average.

- Midwest (Suburban): Near national average.

- Southwest (Rural/Low-density): -5% to -15% below national average.

- Permit Fees: Vary significantly by county and municipality.

- Material Costs: Can fluctuate based on regional supply and demand.

- Crew Availability: In areas prone to frequent power outages or during peak seasons, demand for installers can drive prices up.

Seasonality: Timing Your Install

Scheduling your installation during off-peak seasons can sometimes lead to better pricing or faster service.

- Peak Season: Typically late spring through fall, when hurricane season or severe weather events are top of mind, or after major power outages. Installers are busiest, and prices may be less flexible.

- Off-Peak Season: Winter (outside of immediate post-storm periods) or early spring can be slower times for installers, potentially offering more competitive quotes or greater scheduling flexibility.

Saving Smart: How to Reduce Generac Generator Installation Costs

While quality and safety should never be compromised, there are intelligent ways to manage and potentially reduce your overall investment.

Right-Sizing Your Generator for Essential Loads

This is perhaps the biggest cost-saving opportunity. Many homeowners initially think they need a generator large enough to power their entire home. However, powering only essential circuits can significantly reduce both the generator's unit cost and the associated installation expenses (smaller ATS, less demanding electrical upgrades).

- Perform an Energy Audit: A qualified installer can help you identify your home's critical loads (e.g., well pump, refrigerator, furnace, medical equipment) versus non-essential ones (e.g., guest room lights, hot tub).

- Prioritize: Decide what you truly need during an outage versus what would simply be convenient. A smaller generator focused on critical items can often provide plenty of peace of mind at a lower price point.

Comparing Quotes from Certified Installers

Always obtain at least three quotes from different Generac-certified dealers and installers. This allows you to:

- Compare Pricing: See how different companies price the same scope of work.

- Assess Scope: Ensure each quote includes the same components and services (e.g., permits, concrete pad, fuel line, electrical upgrades).

- Gauge Expertise: A reputable installer will perform a thorough in-home assessment, asking detailed questions about your energy needs and site specifics. This free assessment is crucial for an accurate quote.

- Check References and Licensing: Verify that installers are licensed, insured, and have a good reputation.

Considering Off-Peak Season Installation

As mentioned, scheduling your installation during slower periods for installers could lead to more competitive bids and better scheduling flexibility. If you're not facing an immediate threat of power outages, waiting for the off-season might save you a few hundred dollars.

Exploring Rebates and Incentives

Keep an eye out for potential financial incentives that could offset your costs:

- Utility Company Rebates: Some local utility companies offer rebates for installing energy-efficient appliances or standby generators, especially if they help stabilize the grid during peak demand.

- Local Government Programs: Occasionally, state or local governments offer tax credits or incentives for home improvements that enhance safety or resilience.

- Insurance Discounts: Some home insurance providers offer small discounts for homes equipped with standby generators, as they can prevent damage from prolonged outages (e.g., burst pipes from frozen plumbing).

Always inquire with your installer, utility provider, and local government about any available programs.

Common Questions About Generac Generator Installation

How long does Generac generator installation take?

Most standard Generac standby generator installations are completed within one to two days of the crew arriving on site. However, the entire process, from initial consultation and permitting to final inspection and commissioning, can take several weeks to a few months, depending on permit approval times, utility company lead times (for gas meter upgrades), and installer scheduling.

Can I install a Generac generator myself?

No, installing a Generac standby generator is not a DIY project. It involves complex electrical wiring, gas line connections, and adherence to strict local building and safety codes. Attempting a self-installation can void your warranty, lead to dangerous electrical hazards (like backfeeding the grid), cause gas leaks, result in failed inspections, and incur significant fines. Always use Generac-certified and licensed professionals.

What's the difference between a portable and a standby generator for installation?

- Portable Generators: These are manually operated, run on gasoline or propane, and typically connect to your home via an extension cord or a manual transfer switch. Installation is minimal, usually just connecting to a transfer switch and having an outdoor hookup.

- Standby Generators: These are permanently installed, automatically turn on when power is lost, and connect directly to your home's electrical and fuel systems. Their installation is extensive, requiring a concrete pad, dedicated fuel lines, an automatic transfer switch, and significant electrical work, as detailed throughout this guide. The "installation cost" discussion primarily refers to standby generators.

Do Generac generators add value to my home?

Yes, a professionally installed Generac standby generator can add significant value to your home, often between 3% and 5% of the home's value, and sometimes more in areas prone to frequent outages. It's a highly desirable feature for potential buyers, offering peace of mind, comfort during outages, and protection for appliances and critical systems. It can also be a strong selling point in competitive real estate markets.

Your Next Steps: Getting a Precise Generac Installation Quote

Understanding the various cost components is a critical first step. The next, and most crucial, is to get an accurate, personalized quote for your specific home and needs.

Here's how to proceed:

- Assess Your Needs: Have a clear idea of what you want to power during an outage. Are you looking for essential circuit backup, or whole-house comfort? This will help guide the discussion with installers.

- Schedule In-Home Assessments: Contact several Generac-certified dealers or installers in your area. Request a free, no-obligation in-home assessment. A good installer will visit your property, evaluate your electrical system, measure distances for fuel and electrical runs, and discuss placement options.

- Request Detailed Quotes: Ensure each quote is itemized, clearly breaking down the cost of the generator unit, the automatic transfer switch, labor, materials, electrical upgrades, site preparation, permits, and any other associated fees. Don't forget to confirm whether sales tax is included.

- Ask Questions: Don't hesitate to ask about warranties, maintenance plans, and expected timelines. Clarify anything that's unclear in the quote.

- Compare and Choose: Review all quotes thoroughly. Don't just pick the lowest price; consider the installer's reputation, experience, proposed solution, and customer service.

Investing in a Generac standby generator is a significant decision that brings invaluable security and comfort to your home. By understanding the factors that influence Generac generator installation costs and diligently researching your options, you can make a confident choice that safeguards your home and family for years to come.