Power outages are an inconvenient fact of life, and for many homeowners, a Generac standby generator is the ultimate peace-of-mind solution. But while the initial purchase price is a one-time hit, understanding your Generac Generator Operating & Maintenance Expenses is key to truly budgeting for uninterrupted power. Just like owning a car, a generator needs consistent care to perform reliably when you need it most. Skip the routine, and you risk not only a hefty repair bill but, worse, a silent generator during your next blackout.

This guide will demystify the ongoing costs of owning a Generac, offering a transparent look at what to expect, why costs vary, and how smart decisions can save you money without compromising reliability.

At a Glance: Generac Maintenance Costs

- Typical Annual Cost: Most homeowners pay between $129 to $399 annually for routine maintenance.

- Higher-End Plans: Comprehensive service can reach $500 per year, especially for larger units or bundled services.

- Major Repairs: One-off repairs, parts replacements (like batteries every 2-3 years), or transfer switch work can push annual expenses over $1,000 in specific years.

- Key Cost Drivers: Generator size (kW), fuel type, inspection frequency, service level, local labor rates, and whether parts/fluids are included.

- Labor: Expect 2-5 hours for typical annual service, depending on unit size, at $75-$150 per hour.

- Cost Savings: Fixed-rate plans, self-checks, off-peak scheduling, and smart plan comparisons can reduce your overall spend.

Beyond the Purchase Price: Why Ongoing Generac Care is Non-Negotiable

You've made a significant investment in your home's comfort and security by purchasing a Generac generator. But the sticker price, which you can explore further when considering what Generac generators cost, is only one piece of the financial puzzle. The real long-term value comes from consistent operation and maintenance. Think of your Generac like any other major appliance or vehicle: neglect it, and you're inviting costly breakdowns and premature failure.

Preventative maintenance isn't just about fixing things when they break; it's about ensuring your generator never breaks down when you need it most. It means catching small issues before they become expensive problems, maximizing fuel efficiency, and extending the lifespan of your unit.

What Generac Operating & Maintenance Expenses Actually Cover

When we talk about these expenses, we're generally looking at several categories:

- Routine Maintenance: Scheduled inspections, fluid changes, and filter replacements. This is the bulk of your annual cost.

- Parts & Fluids: The actual consumables like oil, filters, spark plugs, and potentially batteries.

- Labor: The professional technician's time and expertise.

- Non-Routine Repairs: Unexpected fixes for components, often triggered by wear and tear or specific issues.

- Operating Costs: Primarily fuel, which varies widely based on usage.

While fuel costs are directly tied to how often and how long your generator runs, maintenance costs are more predictable, forming a baseline expense to keep your unit ready.

The Main Cost Categories: What You're Actually Paying For

To truly understand your Generac generator operating and maintenance expenses, let's break down the components. Each element contributes to the overall cost, and understanding them empowers you to make informed decisions.

1. Routine Maintenance & Service Plans

The cornerstone of generator longevity is regular, professional service. Most Generac owners opt for an annual maintenance plan, which bundles a series of inspections and services.

- Annual Service: This typically includes changing the oil and oil filter, checking/replacing spark plugs, inspecting the air filter, testing the battery, and a general check of the entire system (fuel lines, electrical connections, transfer switch operation).

- Cost Range: For most residential units, typical yearly maintenance plans fall between $129 and $399.

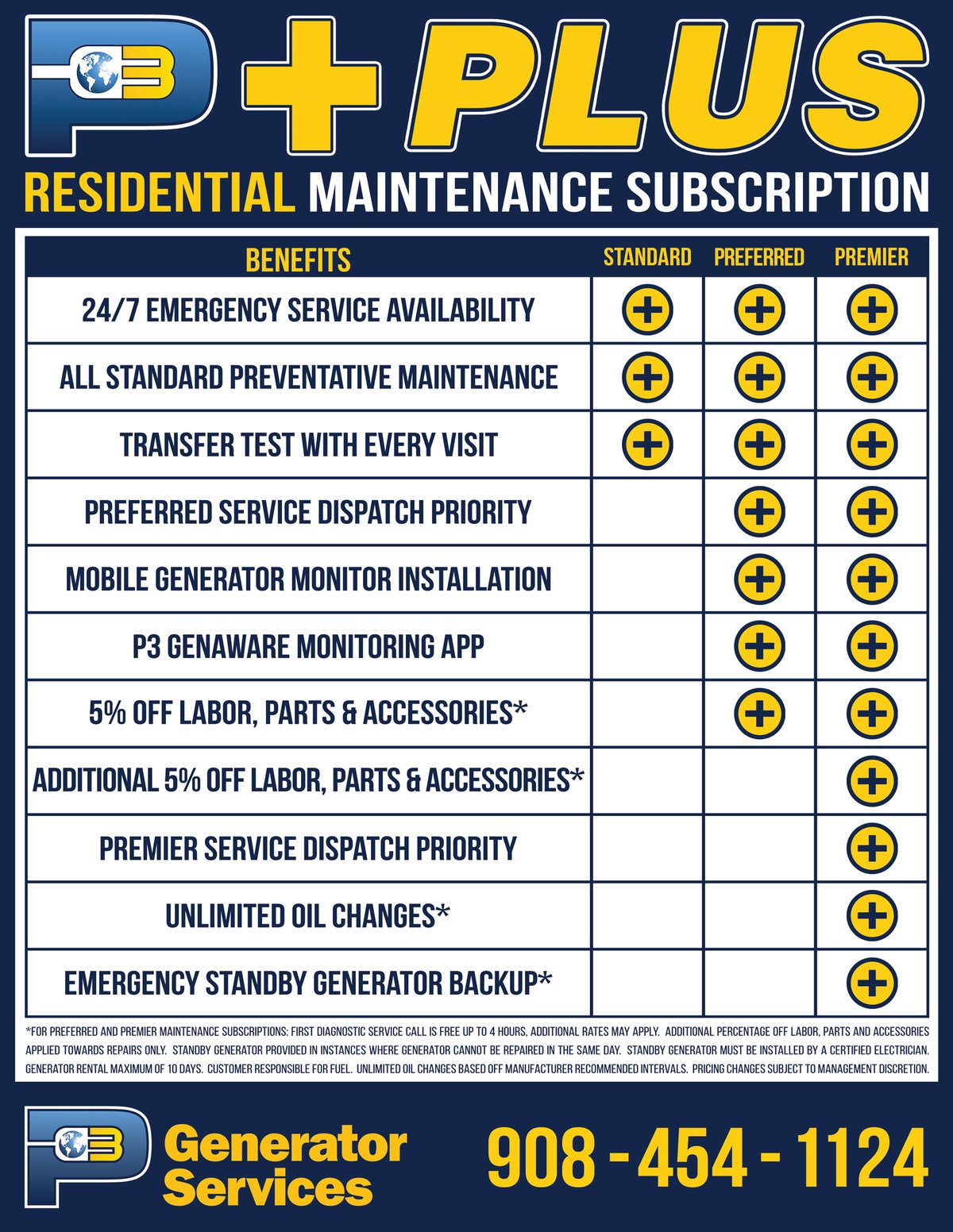

- Comprehensive Plans: For larger units or those seeking maximum peace of mind, plans can extend up to $500 annually. These higher-tier packages often include more frequent visits, premium synthetic oils, battery health checks, transfer switch inspections, and sometimes even priority scheduling or extended warranty benefits.

Choosing a service plan often provides better value than paying for individual services as they arise, offering predictable budgeting and ensuring nothing is overlooked.

2. Parts and Fluids: The Consumables

Every generator runs on more than just fuel; it requires a host of fluids and parts that wear out over time.

- Engine Oil & Oil Filter: Critical for lubrication and cooling. Changed annually.

- Air Filter: Prevents dust and debris from entering the engine. Checked annually, replaced as needed.

- Spark Plugs: Essential for ignition. Checked and replaced annually or biennially.

- Battery: Your generator's starting battery is vital. These typically last 2-3 years and can cost anywhere from $100 to $300 for the battery itself, plus labor for replacement. It's often not included in basic annual plans.

- Fuel Filter: For units running on diesel or sometimes propane, fuel filters need periodic replacement to ensure clean fuel delivery.

- Coolant: For liquid-cooled units (typically larger, commercial-grade residential units), coolant levels and condition need monitoring.

The cost of these parts and fluids will vary slightly based on your generator's model and local supplier pricing.

3. Labor Rates: The Expertise Behind the Service

A significant portion of your maintenance cost goes towards the skilled technician's time.

- Hourly Rates: Local labor rates for certified generator technicians commonly range from $75 to $150 per hour. This variation depends heavily on your geographic location, the technician's certifications, and the service company's overhead.

- Regional Differences: Urban areas often have higher base rates but better technician availability. Rural areas might show lower base rates but could include higher travel fees. Suburban markets tend to offer a balance. These regional shifts can affect quotes by as much as 20-35 percent.

- Time Commitment:

- 8-12 kW units: Typically require 2-3 hours for a standard annual inspection and fluid service.

- 12-16 kW units: Also fall within the 2-3 hour range for typical annual service.

- 20 kW+ systems: Can take 3-5 hours due to more components, larger fluid capacities, and potentially more extensive checks.

- Heavier commercial units (20-60 kW): May exceed 5 hours.

When comparing quotes, always clarify how many hours are estimated for the service.

4. Non-Routine Repairs & Emergency Calls

While preventative maintenance aims to minimize these, unexpected issues can still arise. These are typically not covered by standard maintenance plans.

- Transfer Switch Issues: The automatic transfer switch is a critical component that can sometimes require servicing or repair, which can be complex and costly if not part of a comprehensive plan.

- Sensor Failures: Generators rely on various sensors (oil pressure, temperature, etc.) that can malfunction.

- Component Replacements: Beyond routine parts, components like starters, alternators, or control boards can fail.

- Emergency Call-Outs: If your generator fails during an outage, an urgent service call will likely incur higher hourly rates or a dedicated emergency fee.

Having a robust maintenance history can sometimes influence how quickly a technician can diagnose and resolve such issues.

Key Factors Driving Your Generac Maintenance Costs (The "Why")

Why do some homeowners pay more than others for their Generac's upkeep? Several variables are at play. Understanding these factors can help you anticipate costs and make smarter choices.

1. Generator Size (Kilowatts - kW)

This is one of the most significant determinants of maintenance cost. Larger generators typically mean:

- More Fluids: Greater oil capacity, more coolant (for liquid-cooled units).

- More Parts: Larger air filters, more spark plugs, potentially more robust batteries.

- Longer Labor Times: More components to inspect, more complex systems to test. As detailed above, a 20 kW unit can take twice as long to service as an 8 kW model.

- Complexity: Larger units often include more advanced features or require specialized tools, affecting labor.

If you're still deciding on a unit, consider how choosing the right Generac size impacts both upfront and ongoing expenses.

2. Fuel Type

Generac generators primarily run on natural gas or liquid propane (LP), with some larger units using diesel. The fuel type can influence specific maintenance needs:

- Natural Gas/LP: Generally cleaner-burning, which can extend the life of certain engine components. However, they still require specific fuel filters or regulator checks.

- Diesel: May require more frequent fuel filter changes, and potentially fuel additives to prevent gelling in cold weather.

For a deeper dive into fuel considerations, you might want to learn more about understanding Generac fuel efficiency.

3. Service Level & Plan Inclusions

Not all maintenance plans are created equal.

- Basic Inspection: A visual check, oil level check, and a run test. Minimal cost, minimal coverage.

- Standard Annual Service: Includes oil/filter change, spark plug check, battery test, system run-through. This is the most common residential plan.

- Premium/Comprehensive Plans: May include synthetic oil, all parts and labor, transfer switch inspection, battery replacement, priority service, and even remote monitoring. These naturally come at a higher price point but offer greater predictability and peace of mind.

4. Inspection Frequency

While annual service is standard, some heavy-use scenarios or specific environmental conditions might warrant bi-annual checks. More frequent visits mean higher annual costs but can be a wise investment for mission-critical applications or very dusty environments.

5. Local Labor Rates & Regional Variations

As mentioned, where you live significantly impacts technician costs. Seasonal demand also plays a role. Scheduling service before peak demand periods (e.g., hurricane season) can sometimes lead to better rates or availability.

6. Age of Unit & Warranty Status

Newer units under Generac warranty coverage might have certain parts and labor covered for specific failures, reducing out-of-pocket costs for unexpected repairs. Older units, however, might start to require more frequent part replacements as components age and wear out, increasing maintenance costs over time.

7. Environmental Factors

Generators installed in extremely dusty, humid, or corrosive environments (e.g., coastal areas) may require more frequent filter changes or inspections to prevent premature wear.

Real-World Scenarios: What You Might Actually Pay Annually

To give you a clearer picture, here are some common scenarios for residential Generac generator operating and maintenance expenses, drawing directly from typical service offerings:

| Scenario | Generator Size (kW) | Service Inclusions | Estimated Labor Time | Total Annual Cost Range |

|---|---|---|---|---|

| Basic Maintenance | 8-12 kW | Annual inspection, oil check, oil filter change, spark plug inspection. All parts and fluids included. | 2 hours | $140 - $210 |

| Mid-Range Service | 12-16 kW | Annual service as above, PLUS battery health check, transfer switch inspection, air filter check/replacement. | 2.5 - 3.5 hours | $210 - $320 |

| Premium Service | 20-24 kW | Full annual service with synthetic oil, all filters, battery testing/replacement, full system diagnostics, disposal fees. | 4 - 5 hours | $350 - $520 |

| Note: These ranges are estimates. Actual costs can vary based on your specific location, service provider, and additional services requested. |

Actionable Strategies to Reduce Generac Operating & Maintenance Expenses

While some costs are unavoidable, there are smart ways to minimize your Generac generator operating and maintenance expenses without sacrificing reliability.

1. Embrace Fixed-Rate Maintenance Plans

Many dealers offer annual service contracts that bundle labor, parts, and sometimes even emergency call discounts into a single, predictable fee.

- Why it helps: Provides budget certainty, often includes a discount compared to ad-hoc services, and ensures your generator gets consistent, expert attention. Look for plans that consolidate visits to avoid multiple travel charges.

2. Become Your Generator's First Line of Defense: Perform Regular Self-Checks

You don't need to be a certified technician to perform basic, yet crucial, checks.

- Check the Battery: Regularly inspect battery terminals for corrosion and ensure connections are tight. Check the battery's voltage (a simple voltmeter is inexpensive). A weak battery is the most common reason a generator fails to start.

- Monitor Run Tests: Your Generac automatically runs weekly/bi-weekly self-tests. Pay attention! Does it start smoothly? Does it run for the full duration? Does it sound normal? Any unusual noises or error codes should prompt a professional check, potentially preventing serious troubleshooting common Generac issues later.

- Visual Inspection: Keep the area around your generator clear of debris, overgrown vegetation, and pests. Check for any visible leaks.

- Why it helps: Reduces the need for emergency service calls and helps identify minor issues before they escalate.

3. Schedule Annually During Off-Peak Seasons

Demand for generator service surges before hurricane season or winter storms.

- Why it helps: Scheduling your annual maintenance in the spring or fall (e.g., April-May or September-October) can sometimes lead to better pricing, more flexible scheduling, and less rushed service appointments.

4. Compare Service Plans Thoroughly

Don't just look at the price tag. Read the fine print.

- What's Included? Does the plan cover labor and parts? Are specific fluids (like synthetic oil) included? What about battery replacement or transfer switch inspections?

- Emergency Response: Does the plan offer priority scheduling or discounted rates for emergency call-outs?

- Why it helps: Ensures you're getting the best value for your specific needs and avoids unexpected charges.

5. Prepare for Your Technician's Visit

A few minutes of prep can save your technician time, which can translate to savings for you.

- Clear Access: Ensure the generator is easily accessible. Remove any obstacles, snow, or debris.

- Known Issues: Have a list of any observations (e.g., strange noises during a run test, error codes displayed) ready for the technician.

- Why it helps: Reduces labor time spent on site, potentially lowering your overall bill if paying hourly.

6. Opt for Essential Inspections for Tight Budgets

If comprehensive plans are out of reach, prioritize the bare essentials.

- Why it helps: Ensure critical fluid changes and safety checks are performed until your budget allows for more complete maintenance milestones. It's better to do some professional maintenance than none at all.

Beyond Routine: Understanding Unexpected Generac Costs

While annual maintenance covers the predictable, sometimes other costs pop up. Being aware of these helps you budget more effectively for the total cost of ownership.

Battery Replacements

As mentioned, your generator's battery is usually a separate expense from annual service. These typically need replacing every 2-3 years, costing $100-$300 for the battery itself, plus labor. A dying battery is the number one culprit for a generator failing to start during an outage.

Transfer Switch Service

The automatic transfer switch (ATS) is the brain that tells your generator to start and routes power to your home. While often visually inspected during routine service, complex issues with the ATS may require specialized diagnostic and repair work, which can be an additional, significant cost. Ensure your maintenance plan clearly outlines what, if anything, is covered regarding the ATS. The quality of your Generac installation also impacts the long-term reliability of the transfer switch.

Software Updates and Firmware Issues

Like any modern appliance, Generac generators rely on control boards and software. Occasionally, updates or diagnostics might be needed, especially if your unit is experiencing unusual behavior or error codes. These are typically handled by authorized technicians.

Pest Damage

Animals, particularly rodents, love to nest in warm, sheltered spaces like generator enclosures. They can chew through wires, build nests, and cause significant damage that falls outside routine maintenance. Keep the area clear and consider pest deterrents.

Out-of-Warranty Repairs

Once your Generac's warranty expires, any significant component failure (e.g., engine issues, major electrical component failure) will be entirely out-of-pocket, potentially running into hundreds or thousands of dollars. This underscores the value of preventative maintenance in extending component life.

The ROI of Diligent Maintenance: Why It's Worth Every Penny

Investing in Generac generator operating and maintenance expenses isn't just about spending money; it's about protecting a significant asset and ensuring its performance. The return on investment (ROI) is substantial:

- Extended Lifespan: A well-maintained generator can last 20-30 years or more. Neglect can cut that lifespan in half, forcing an early, costly replacement.

- Unwavering Reliability: The primary reason you bought a Generac was for reliable power during outages. Consistent maintenance ensures it will start and run when you need it most, providing the peace of mind you paid for.

- Optimal Performance & Fuel Efficiency: Clean filters and fresh oil mean the engine runs more efficiently, potentially saving you a bit on fuel during longer outages.

- Higher Resale Value: Should you ever sell your home, a meticulously maintained generator with a detailed service history is a major selling point.

- Avoid Costly Breakdowns: Preventative care catches small problems (like a weak battery or a dirty spark plug) before they become catastrophic failures (like engine damage), saving you from much larger repair bills.

Ultimately, your Generac is there to protect your home and family. Its ongoing care is an investment in that protection.

Choosing the Right Service Provider

Selecting the right company to service your Generac is as important as the service itself.

- Authorized Generac Dealers: These technicians are specifically trained and certified by Generac, ensuring they have the latest knowledge, tools, and access to genuine Generac parts.

- Independent Technicians: Some independent electricians or HVAC companies may service generators. Ensure they are properly licensed, insured, and have specific experience with Generac units. Ask about their certifications.

- Reputation and Reviews: Check online reviews and ask for local references.

- Transparency: A reputable provider will clearly outline what's included in their service plans and provide detailed invoices for any additional work.

Establishing a relationship with a trustworthy service provider ensures your generator receives consistent, expert care, building on the foundation of a proper initial setup.

Your Next Steps: Taking Control of Your Generac's Health

You now have a comprehensive understanding of the Generac generator operating and maintenance expenses involved in owning your standby power solution. The next step is action.

- Review Your Current Status: Check your generator's last service date and battery age.

- Evaluate Your Needs: Consider your generator's size, age, and local environmental factors.

- Get Quotes: Contact at least two to three authorized Generac dealers or reputable technicians in your area. Ask for detailed breakdowns of their annual maintenance plans, clarifying what's included (parts, labor, battery checks, transfer switch inspections, emergency response).

- Consider a Fixed-Rate Plan: For budget predictability and comprehensive care, a service plan is almost always the best value.

- Start Your Self-Checks: Begin regularly inspecting your battery, clearing debris, and listening to those weekly run tests. Log any observations.

By proactively managing your Generac's maintenance, you're not just spending money; you're investing in reliable power, protecting your home, and ensuring that when the lights go out, yours stay on.